Perfect Binding: A Closer Look at Modern Bookbinding

Our Printing Services

We're providing offset & digital printing services for all types of paper products including books, bags, boxes, or food packaging.

-

Angpao Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Paper Bag Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Calendar Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Chinese Calendar Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Doughnut Packaging Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Pizza Box Printing

Regular price RM0.00 MYRRegular priceUnit price per -

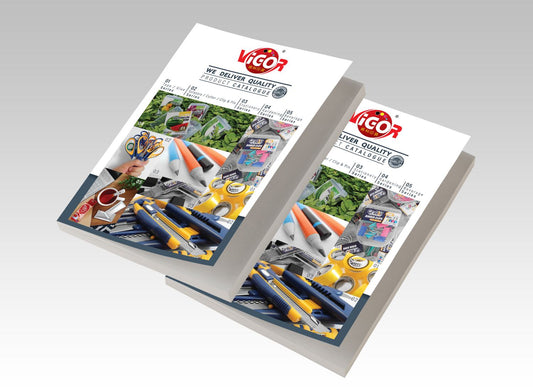

Perfect Binding Book Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Softcover Book Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Stapled Booklet Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Lunch Box Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Paper Food Box Printing

Regular price RM0.00 MYRRegular priceUnit price per -

Novel Book Printing

Regular price RM0.00 MYRRegular priceUnit price per